On site demagnetization becomes necessary when components or machines can’ t be moved with reasonable effort or there is a great time pressure. We use our own portable high power demagnetizer MGFE for this kind of work.

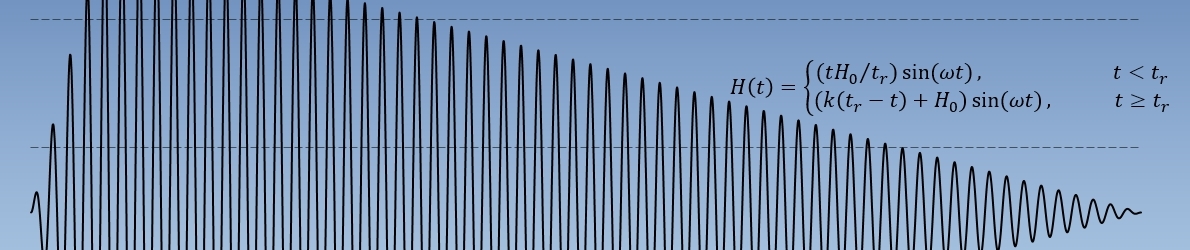

In contrast to other methods, a high precision low frequency sine pulse demagnetization method is used. This technique minimizes the probability of unwanted effects by induced voltages or induced currents to an absolutely uncritical minimum. Therefore, critical components, such as servomotors, sensors, etc., must not be disassembled during the demagnetization of already installed machines, but must only be deactivated.

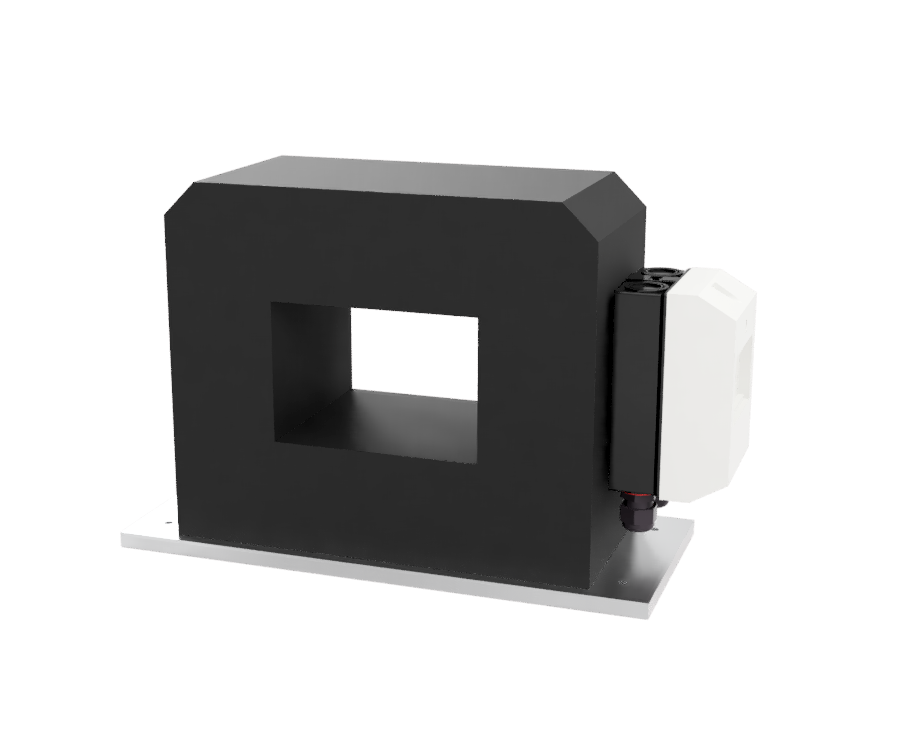

Degaussing of larger special parts with portable demagnetizer MGFE-70

Low frequency demagnetization of a NC spindle. The cable has an innovative safety function against electrical breakdown in case of cable jacket damage

Demagnetization of rotors and shafts with mobile degaussing system

Our systems allow demagnetization of sensitive high precision machines

Further examples:

- Demagnetization of powder presses, adapters and tools.

- Prevention of magnetic problems during welding by demagnetizing the corresponding units on site.

- Demagnetization of NC machines, clamping systems and tools.

- Eliminating residual magnetism in order to prevent shaft voltage issues caused by magnetic fields.

- Demagnetization of rebars (already installed or before concreting).

- Demagnetizing steel products to comply with residual magnetism limits.

- Demagnetization of sensitive medical devices.

Requirements:

- Mains power: 3×380…480VAC, 16…32A, 50/60Hz

This activity is offered internationally. Outside the EU, operations have already been carried out in Australia, Canada and the USA.

More products: