This page introduces briefly basic concepts that are needed for understanding ferromagnetism, hysteresis, flux density and field strength, magnetic attraction forces and finally the main topic demagnetization.

Magnetism of ferromagnetic metals

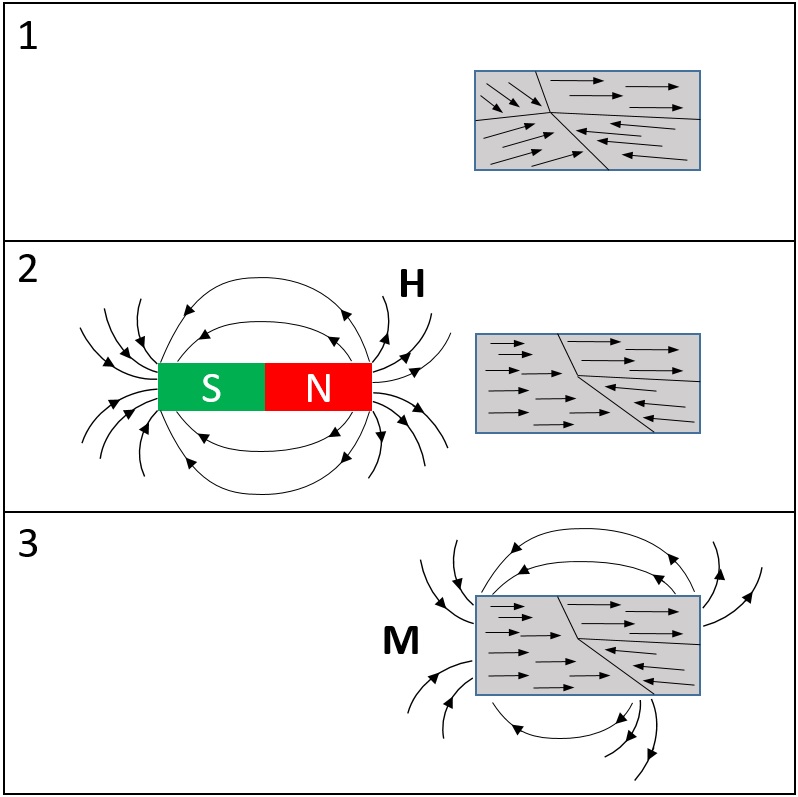

A magnetized ferromagnetic material (e.g. metals like steel, iron…) is characterized by a high number of magnetic domains which are oriented in the same direction or have joined together to form larger magnetic domains. As a result, the magnetic flux of the individual domains adds up to form a greater total flux, which appears as residual magnetism or magnetic stray field outside the ferromagnetic metal. The magnetic field is a vector quantity, characterized by an intensity and a direction (field vector H) . The magnetic field lines flow by definition from the magnetic north pole (N) to the magnetic south pole (S).

However, a demagnetized metal can be magnetized at any time by:

- a magnetic field of sufficiently high intensity

- transformation in the crystalline structure (e.g. forming, bending)

- by passing strong electrical currents through the material

A demagnetized state is a state where aligned domains have been subdivided into smaller domains with random magnetization directions. From this state no substantial magnetization results.

Magnetic hysteresis curve

The magnetic properties of a ferromagnetic material are described by characteristic points in the magnetic hysteresis curve:

During the first magnetization, the material passes through the so called initial magnetization curve from the origin to the saturation point.

Bsat is the saturation flux density. At this point all the magnetic domains of the material are fully aligned due to the external field Hsat.

Br is the remanence of the material. After removal of the Hsat field, the magnetic flux follows the upper curve from the point (Hsat / Bsat) to the point (H=0 / Br). The remanence defines the residual magnetism remaining in the material after saturation magnetization.

Hc is the coercive force of the material. Hc defines how much field strength is required to demagnetize a fully saturated material. The field strength required for the demagnetization must be of opposite polarity (reversing) to the magnetization field strength Hsat, hence -Hc.

The demagnetization with reversing field Hc only works on a magnetized material sample of simple, symmetrical geometry. Technical parts with irregular geometry and made of materials with different magnetic properties (for example hardened parts) must be demagnetized by cycling down the hysteresis curve several times (more information below).

Field strength H and flux density B

The field strength vector H describes the magnetic field strength generated by “free currents” without influence of the magnetization M of matter. By free currents is meant either electric currents in a conductor or magnetic dipole moments at the atomic level. Both sources have a moving charge in common, the electrons.

The magnetic field strength at a distance r [m] around the conductor is defined as follows for a straight conductor:

H = I / 2πr (e1)

The unit is: [H] = [A/m] Ampère/meter

With the magnetization M of matter, the present magnetic field H is defined as flux density B:

B = μ0(H + M) = μ0(H + (μr – 1)H) = μ0μrH (e2)

The unit is: [B] = [T] Tesla

The factors μ0 and μr are the relative magnetic permeabilitiy of the vacuum (constant) and respectively the ferromagnetic material. The relative magnetic permeability (slope in the blue hysteresis curve above) is not constant, but depends on the field H: μr = μr(H).

A magnetically highly conductive material, e.g. transformer sheets (μr over 10,000) has a high relative magnetic permeability. By contrast the following ferromagnetic materials have a low magnetic permeability: hardened martensitic steels, hardmetals (μr below 20) and stainless steels with low ferritic fractions. Austenitic steels are basically non magnetizable and consequently have a magnetic permeability of almost 1.

The relative magnetic permeability indicates how strongly a material can be magnetized at a certain field strength H. It is thus a measure of the permeability of matter to magnetic fields. A material with a high permeability number can be magnetically attracted more strongly.

Magnetic field meters convert between flux density and field strength by setting internally μr = 1. This is permissible because the sensor does not measure “inside” the ferromagnetic material, but always outside of the material, hence in air. In air, μr is approximately 1. From equation (e2) follows: 1mT ^ = 7.96A/cm.

Magnetic attraction

Magnetic fields lead to attraction forces on magnetizable objects and on magnetic fields of opposite polarity.

In the following two equations are introduced by which the magnetic attraction force can be calculated. The first equation (e3) is used to calculate the forces between two surfaces and the second (e4) to estimate the magnetic attraction on small objects (e.g. ferromagnetic particles).

Magnetic attraction force between two surfaces

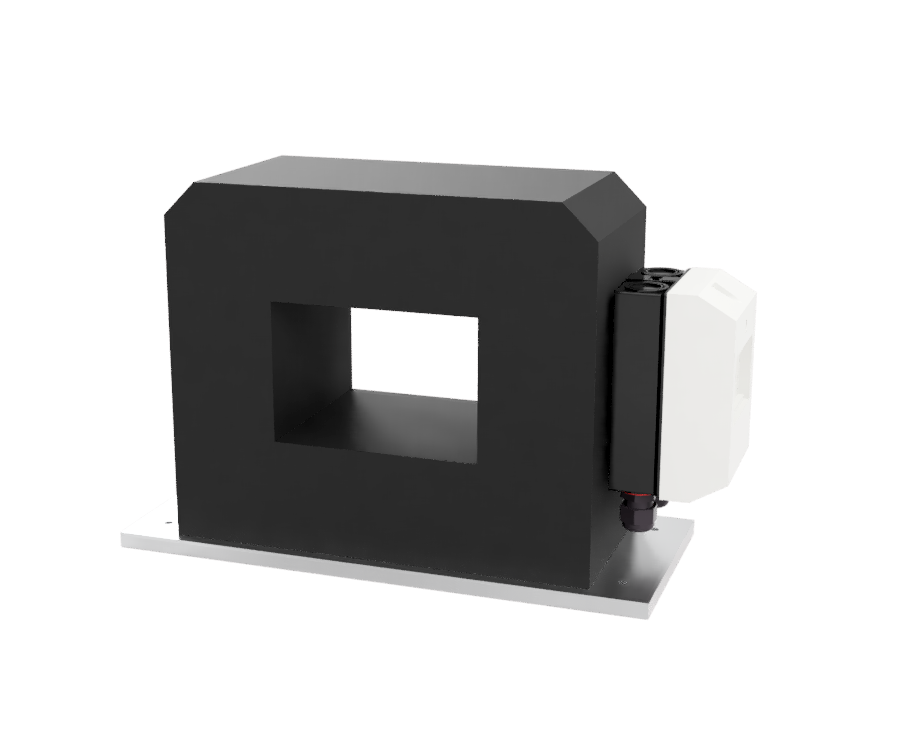

This case is present for example in a yoke with area A and a ferromagnetic object with the same area A lying directly thereabove.

Fm = μ0 · H2 · A/2 (e3)

H: field strength in the air gap between the two surfaces A [m2]

Magnetic attraction force on small objects

The attracting force on small, magnetizable objects, e.g. ferromagnetic particles can be approximated using the following equation:

Fm = μ0 · V · Χ · H · (∇ · H) (e4)

V: volume object [m3]

Χ: magnetic susceptibility (susceptibility: measure of a magnetic property of a material, Χ = μr – 1)

H: Field strength on the object

∇ · H = gradient(H): field strength gradient (gradient: field change/distance)

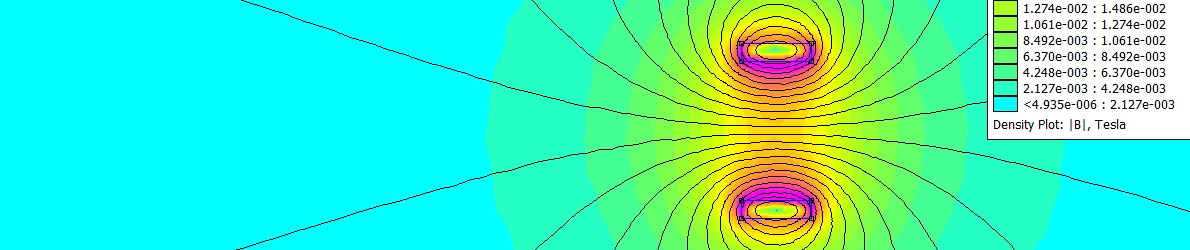

There is again a square relationship between the attracting force Fm and the field strength H. It is also apparent that a high field strength gradient(H) leads to a higher attracting force on ferromagnetic objects.

Ferromagnetic material is always drawn into the direction of increasing field strength. A metal chip is drawn to the edge of a geometry and a part into the corner of a demagnetizing coil, because the highest field strength prevails there. In a completely homogeneous field without field gradients, there is no attracting force on ferromagnetic material.

Magnetic attraction of machined austenitic steel

A frequent case from practice is the need to make austenitic steel (AISI 304, AISI 316 etc.) completely non-magnetic again after machining, deformation etc. so that no magnetic attraction forces or other magnetic interference effects can occur. Mechanical processing can locally lead to an increase in the permeability number due to structural changes (austenite -> martensite).

Demagnetization with alternating field cannot eliminate the magnetic attraction property of an austenitic steel in inhomogeneous fields. The relative magnetic permeability is only minimally changed by the process. Permeability changes can normally only be achieved by special annealing processes.

Why demagnetizing?

The demagnetization of ferromagnetic parts in industry is becoming more and more a necessary process. The subsequent processing of demagnetized parts offers decisive advantages in many areas and it improves the quality of the final products (goto application areas).

Completely demagnetized parts remain demagnetized over very long periods of time when properly handled, stored and transported, without the effect of significant outer magnetic fields.

How to demagnetize?

Ferromagnetic materials can be demagnetized by the following three methods:

- Heating over Curie temperature (the Curie temperature is alloy dependent. For industrial steels it is about 500°C to 800°C and initiates conversion from Ferromagnetism to Paramagnetism).

- Vibrations (reorientation of magnetic domains due to vibration energy).

- Generating an opposing magnetic field so that the magnetic flux drops to zero at a defined measuring point on the material.

- Polarity reversal through decaying alternating magnetic field for the distribution of the magnetic domain magnetization direction (in most cases the method of choice).

Degaussing

Degaussing is another term for demagnetizing. The word degaussing is often used in relation with hard drive erasing machines (also called degaussers) – or in a completely different application – for naval degaussing stations. Such stations are used for demagnetizing whole ships and/or submarines.

In the context of industrial applications, the term demagnetization or demagnetizer is more commonly used.

Demagnetization with decaying alternating field

This demagnetization technique is characterized by an alternating magnetic field with an initially high amplitude, which is subsequently decaying to a lowest possible amplitude. This process seems very simple, but many details are needed to achieve good results.

Decisive process parameters:

- Frequency: rate of change of the polarity reversal. Low frequency for high penetration depth into the material.

- Field strength: intensity of the alternating field. In general, a high field strength is wanted for the reversal of hard magnetic spots in the material.

- Amplitude decrement: the decrement is a measure for the reduction of the alternating field amplitudes.

- Field symmetry: symmetry of the alternating field with respect to the zero field. Symmetry causes the domains to be vortexed without a permanent preference.

- Effective zone: measure for the field volume produced by the coil in which the demagnetizing effect takes place.

- Field homogeneity: measure for the uniformity of the field within the effective zone.

- Fluxing direction: direction of the alternating magnetic field relative to the object to be demagnetized.

These individual parameters must be defined and presented in a demagnetization system in the best possible way. This is our core competence.

Related products: