Pulse demagnetization

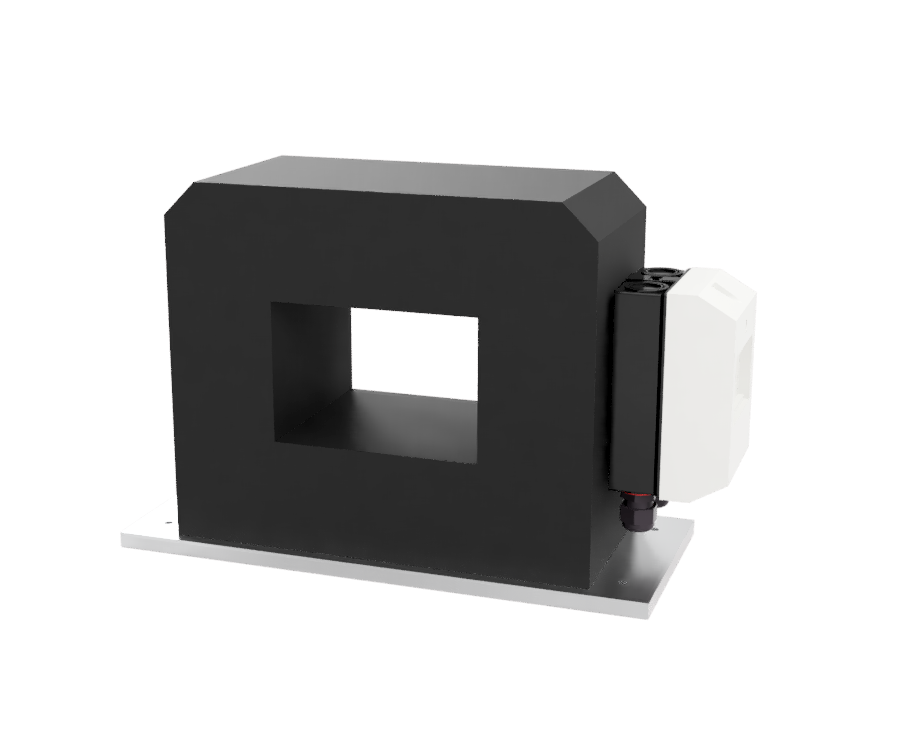

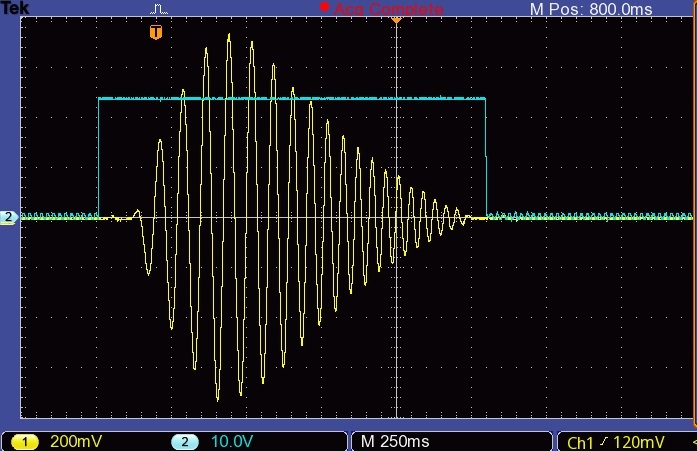

The method is characterized by the precise control of voltage and frequency to provide an optimally tailored AC current pulse flowing through the demag coil. The demag coils are designed to provide maximum performance with the controlled current pulse. The parts to be demagnetized are placed within the effective range of the coil and the pulse is triggered. The pulse parameters are controlled by a modern PLC. The decaying alternating field profile required for demagnetization is highly reproducible and independent of the operator of the system.

The power module constantly feeds current during the decaying field phase according to a programmed demagnetizing curve. The demagnetizing process is thus largely independent of the load of the coil and can be realized with any number of decreasing polarity reversals. As a further advantage, high field strength can be generated by this technology. The heating of the coils is kept under control when operating in pulse mode (short duty cycle at high power).

The progressive frequency pulse demagnetization method developed by Cestriom GmbH offers decisive technological advantages:

- Reduced safety distance with regard to personal protection

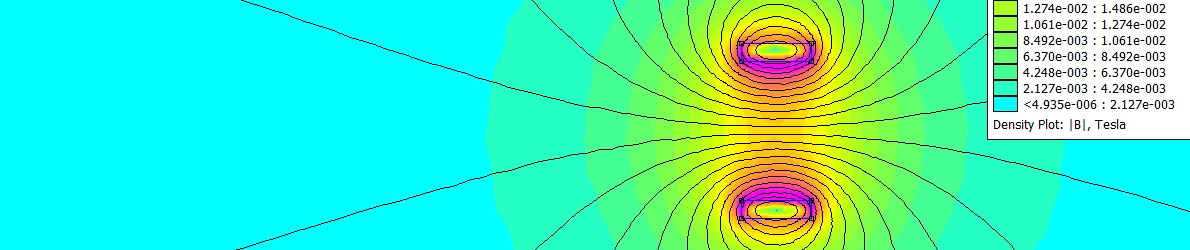

- High penetration depth of the demagnetizing effect

- Short demagnetization pulse duration

Our power modules are only equipped with industrially proven components. The PLC software and the programming of the current sources is our own know-how. This technical concept allows the demagnetizing pulse to be mastered down to the smallest detail and thus allows us to optimally design it for your application.

The coils and power modules are coordinated with each other by means of a calculation based simulation. This ensures the greatest possible demagnetizing effect and a long lifetime of the machine.

If the requirements should once change, an already delivered demagnetization machine is easily adapted to a new situation by readjusting software and programming.

We keep the core technologies completely in our own hands.

Continuous demagnetization

The continuous process is a well known method for the demagnetization of ferromagnetic materials. The demag coils are either connected directly to the mains supply (230VAC or 380…480VAC 50/60Hz) or operated by power modules or low-frequency generators. The alternating field of the coil is constant according to the mains voltage in the first case. In the second case, when operating with power modules, specific frequencies and current levels can be set. This makes the system even more adaptable to a particular case.

The decreasing field amplitude required for demagnetization is achieved by increasing the distance between the coil and the object to be demagnetized (e.g. passage of the parts through a coil with conveyor belt).

The continuous process is particularly suitable for the demagnetization of bars, profiles or pipes. The best results are achieved in combination with DC bias field adjustment for optimum field symmetry.

The maximum field strength is limited due to the substantially higher duty cycle and thus increased coil heating when compared to the pulse method. Pulse demagnetization offers therefore much more performance for the demagnetization of “magnetically difficult” parts.

Related products: