Cestriom industrial demagnetizers are made of high power demagnetizing coils and optimally adapted power modules. The digitally controlled power modules guide precisely the demagnetization process. This approach enables efficient solutions for demanding applications. In high field applications, the demagnetizer machines are usually set for the pulse method. In continuous or endless material flow applications, the machines are configured for a continuous demagnetization process.

The product range includes many variants of power modules and demagnetizing coils (see tables below). When standard sizes do not fit, Cestriom Engineers can design specific systems.

Typical applications of these industrial demagnetization machines are:

- Demagnetizing parts in transport or washing baskets prior to cleaning machines

- Demagnetizing parts before eddy current testing or magnetic particle testing

- Demagnetization of produced components to meet residual magnetism limits

- Eliminating residual magnetism in tools, clamping or gripping elements

- Demagnetization of semi finished steel products

Our industrial demagnetizers are not only suitable for very specific applications. They are also interesting where an economical and universal solution is required for industrial production.

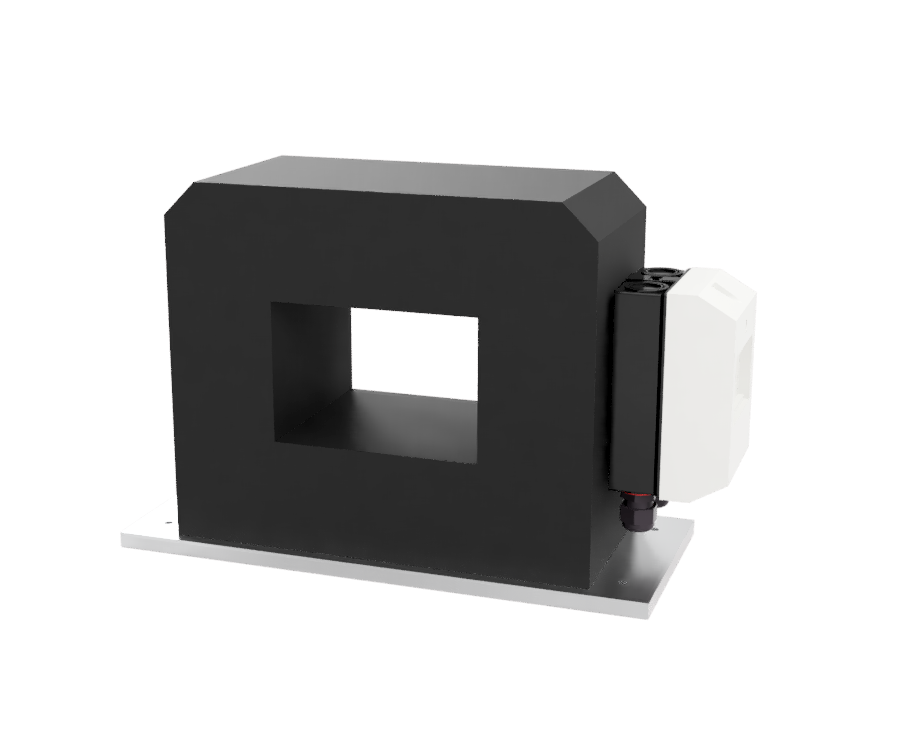

Industrial demagnetizer LM14 + SSM03

Power module LM120 with coil SSM-Sonder

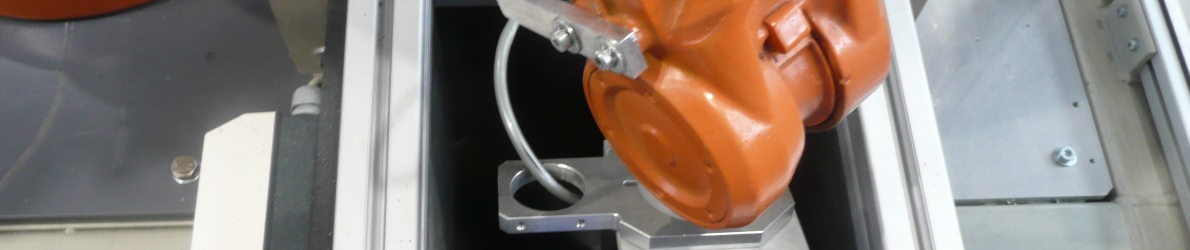

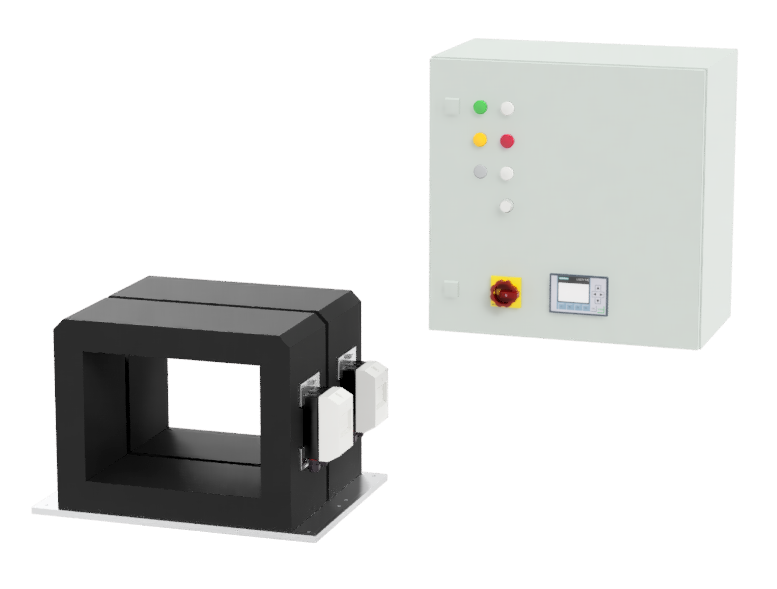

Demagnetizer machine with two coils LM68 + 2x SSM11

Demagnetizing coils:

The windings of the demagnetizing coils are designed for maximum field strength and lifetime. The coils are completely encapsulated, electrically insulated and protected against overheating by temperature monitoring.

Specifications:

| Demag. coil | Active area (1) WxH xD [mm] | Dimension WxH xD [mm] | Power module (2) |

| SSM03 | 150×100 x130 | 408×282 x170 | LM14…LM20 |

| SSM04 | 250×250 x160 | 510×405 x200 | LM14…LM47 |

| SSM05 | 250×350 x210 | 510×505 x250 | LM20…LM68 |

| SSM06 | 260×130 x145 | 520×315 x185 | LM14…LM47 |

| SSM07 | 350×300 x210 | 610×455 x250 | LM20…LM68 |

| SSM08 | 350×450 x210 | 610×605 x250 | LM25…LM68 |

| SSM09 | 400×200 x210 | 660×355 x250 | LM25…LM68 |

| SSM10 | 400×400 x210 | 660×555 x250 | LM25…LM68 |

| SSM11 | 420×300 x210 | 680×455 x250 | LM25…LM68 |

| SSM12 | 550×550 x210 | 810×705 x250 | LM38…LM68 |

| SSM13 | 560×350 x210 | 820×505 x250 | LM38…LM68 |

| SSM14 | 710×550 x210 | 970×705 x250 | LM38…LM68 |

| Other on request |

(1) The active area defines the volume of the coil enveloped by the winding. The dimension WxH corresponds to the passage of the coil.

(2) Standard power modules for a coil. Other combinations on request.

The performance data (field strength, frequency, demagnetization method etc.) is determined optimally in a project specific manner.

Power modules:

The power module contains the power electronics for generating the controlled alternating current required in the demagnetizing coil. We trust for a long term worldwide availability of spare parts exclusively on hardware from leading electronics companies. Cestriom holds the core know-how in its own hands by designing the power modules, programming the PLC’s and setting the power electronics on its own.

Our power modules are designed for simple maintenance and high availability. All relevant settings and parameters are stored completely digitally. This concept not only allows know-how protection, but also permits easy restoring of parameters. The digital design with most recent electronics furthermore enables modern remote maintenance concepts by internet.

The power modules are designed by standard for manual and remote operation. Communication is done via 24V isolated signals in automated (remote) operation mode (further communication variants on request). The demagnetization process parameters are controlled by a PLC. All relevant parameters can be easily changed on a digital display.

Specifications:

| Power module | Electrical connection | Dimension WxH xD [mm] |

| LM14…LM20 | 200…240VAC 50/60Hz, 16A | 400×500 x210 |

| LM25…LM68 | 3×380…480VAC 50/60Hz, 16…32A | 600×600 x350 |

| LM90…LM120 | 3×380…480VAC 50/60Hz, 32…63A | 800x1000x400 |

| Other on request |

- Options on request

Demagnetizer machine examples:

LM14 and coil SSM03 for manual demagnetization of bulk material parts.

LM68 with coil SSM12 for demagnetization of steel parts of different dimensions. Customer realization of the housing.

LM68 with two SSM12 coils in Helmholtz arrangement for demagnetization of parts in washing baskets in front of a cleaning system. Implementation of automation by third party company.

More products: