The continuous demagnetization process is often applied in industrial production due to the way the parts are handled. In most cases continuous demagnetization is carried out by passing the parts through a tunnel demagnetizer coil with constant alternating field and subsequent distance increase to achieve the needed decaying field. Technically, this is done either manually by hand or as usual today, by a conveyorized demagnetizer.

The demagnetizing effect of such tunnel or loop demagnetizers with mains connection 50/60 Hz is limited in materials with large wall thickness, high coercive field strength (hardened steel) and in multi part demagnetization in carriers or as bulk material. In such cases pulse demagnetization with industrial demagnetizer machines is far more effective.

Continuous demagnetization examples. Demagnetizing of:

- small pieces with thin wall thickness

- sheet metal parts up to a few millimeters of wall thickness

- rods or pipes of low wall thickness

- endless parts flow on conveyorized demagnetizers belts

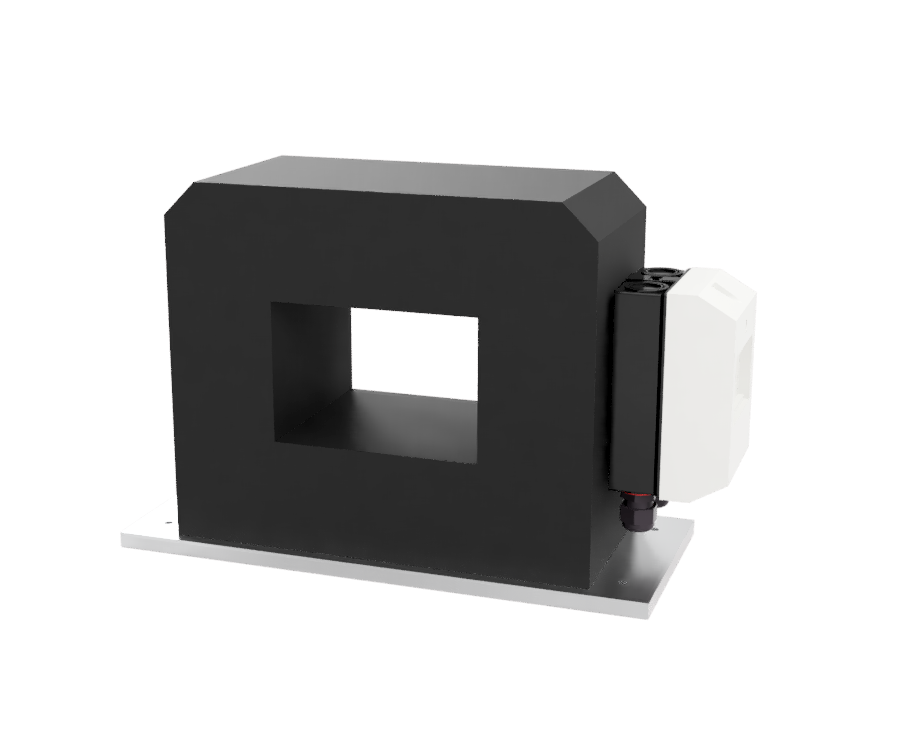

Specifications type DS tunnel demagnetizer:

| DS | Electrical conn. (1) | Active area WxH xD [mm] (2) | Field strength [kA/m] (3) |

| DS03 | 230/277V 50/60Hz | 150×100 x130 | 26 |

| DS04 | 230/277V 50/60Hz | 250×250 x160 | 22 |

| DS05 | 230/277V 50/60Hz | 250×350 x210 | 18 |

| DS06 | 230/277V 50/60Hz | 260×130 x145 | 30 |

| DS07 | 230/277V 50/60Hz | 350×300 x210 | 18 |

| DS08 | 230/277V 50/60Hz | 350×450 x210 | 17 |

| DS09 | 230/277V 50/60Hz | 400×200 x210 | 26 |

| DS10 | 400/480V 50/60Hz | 400×400 x210 | 18 |

| Other on request |

(1) A reduced duty cycle of approx. 30% allows the connection of a 230/277VAC coil to 400/480VAC in order to increase the field strength.

(2) The dimension WxH corresponds to the passage of the coil.

(3) Maximum field strength (peak value) at 100% duty cycle.

More Products: