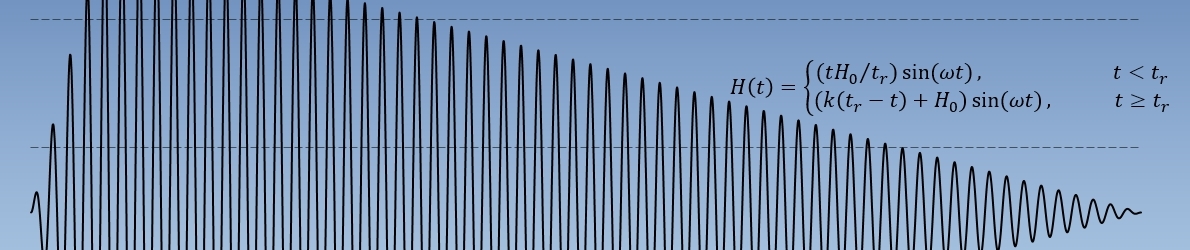

The magnetic field devices MGFE are mobile systems for demagnetization and magnetization of ferromagnetic components. The focus of the devices is on precise demagnetization. Technologically, demagnetization is performed with precise alternating field sine wave pulses, which generate their effect in magnetic field coils.

Flexible magnetic field cables are suitable as a coil system for demagnetizing individual components or entire machines. The parts to be demagnetized are wrapped with the magnetic field cables, or the cable wound into a coil is placed on the relevant part surfaces. Difficult-to-reach places can usually be easily reached due to the flexibility of the magnetic field cables. The magnetic field cables can be coupled to increase the length and thus the number of turns and field strength.

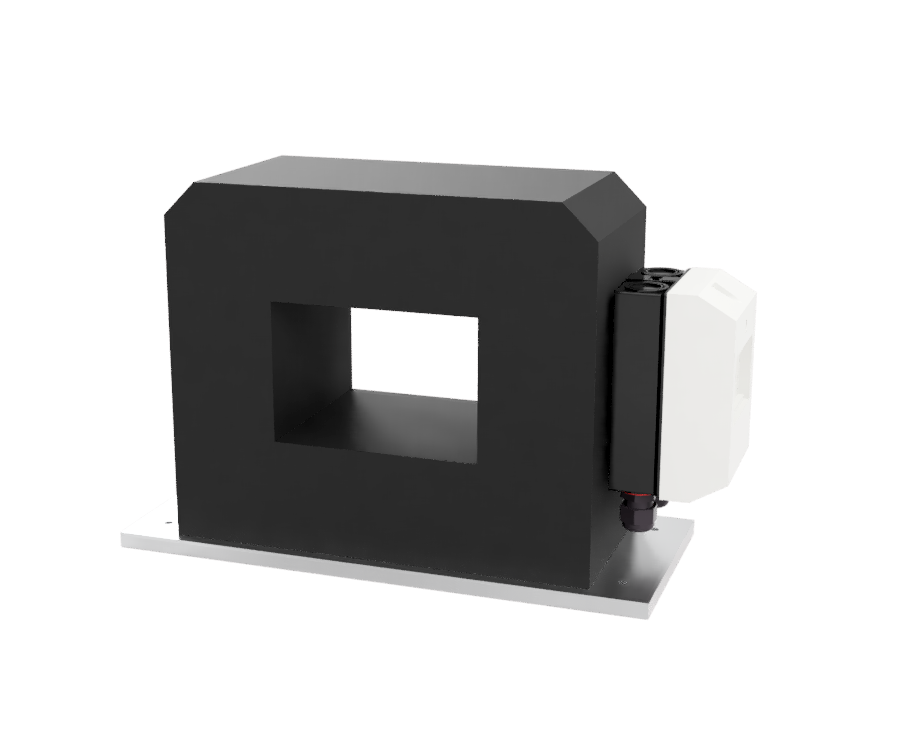

In addition to the magnetic field cables, coils of the SSM series can also be used with the MGFE demagnetizers. For special cases we can also develop special coils with specific dimensions, field strengths or field profiles.

The successful use of the MGFE demagnetizing equipment is ensured with a one to two-day training course. This training takes place either classically at the customer’s site or online via video conference.

Technological functions:

- Demagnetization with low frequency sine pulse and precisely controlled field progression. Demagnetization with low frequency reduces eddy currents and thus causes high penetration depth in ferromagnetic material.

- Demagnetization with sine wave pulse and progressive frequency technology. The increasing frequency in the decay phase of the sine pulse is particularly effective on small and medium-sized parts, as well as on surfaces

- Generation of DC field of adjustable amplitude and polarity, for defined magnetic fluxing and/or magnetization of steel parts.

- Function for precise adjustment of magnetic symmetry. With this function, the magnetic field can be adjusted at defined points on a steel part (for example, at the ends of a steel shaft).

Specifications demagnetizer MGFE:

| Variant | Electrical connection | Max. power [kVA] | Dimensions WxH xD [mm] | Weight [kg] |

| MGFE-30 | 1×200…240VAC 50/60Hz, 16A | 6,5 | 680×530 x380 | ~24 |

| MGFE-70 | 3×380…480VAC 50/60Hz, 32A | 27,2 | 680×530 x380 | ~24 |

- High magnetic flux: With winding diameter 500mm up to 30’000 AWdg with 4 magnetic field cables and MGFE-70. (With MGFE-30 approx. 17’000 AWdg)

- High precision demagnetization with alternating field sine pulse

- Very high repeatability of current profile and extensive field control adjustment possibilities

- Flexible magnetic field cables with different lengths, cross sections, and numbers of active conductors

- Use of SSM series coils or special coils

- Mobility: Lightweight, impact-resistant plastic case on wheels

Examples of use:

Options:

Further applications:

- Demagnetization in relation with non-destructive testing: in particular magnetic particle testing (MT) and eddy current testing (ET)

- Rotating equipment: demagnetization of shafts, bearing seats, housings, preparation for electrical runout tests with eddy current. Reducing residual magnetism induced shaft voltage.

- Mechanical engineering and tool making: demagnetizing of tools, machine parts, etc.

- Steel trade, supplier industry: Demagnetization to comply with residual magnetism limits

- Welding: Demagnetization as process preparation before welding

- R&D: special applications

More products: